Process Capability (Cp & Cpk) |

您所在的位置:网站首页 › test capability › Process Capability (Cp & Cpk) |

Process Capability (Cp & Cpk)

|

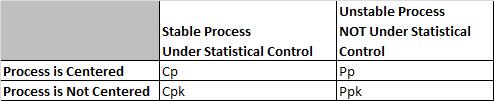

Cp and Cpk are considered short-term potential capability measures for a process. In Six Sigma, we want to describe the process quality in terms of sigma because this gives us an easy way to talk about how capable different processes are using a common mathematical framework. In other words, it allows us to compare an apple process to an orange process! Process CapabilityThis is a long article, but I thought it was important to keep Cp and Cpk together. First, I’ll address Cpk, then Cp. There are also crib notes on what the equations mean in a real performance sense, what you should be able to tell about a process depending on Cp and Cpk values, and more. Please let me know in the notes below if you do not find what you are looking for. Before We Begin!I wrote this article to help Six Sigma Green Belt and Black Belt candidates prepare for and pass their exams. If that’s you, leave me a comment below or contact me and let me know which organization and belt you’re studying for. This will help me make the article even better for you. If you’re studying for something else, please leave a comment or contact me and let me know what you are studying for. Again, this will help me improve the article for you and everyone else. Thanks, Ted. What is the Difference between Cp, Cpk and Pp, PPk? Cp Cpk vs Pp Ppk Cp Cpk vs Pp Ppk

Cp and Cpk are called Process Capability. Pp and Ppk are called Process Performance. In both cases, we want to try to verify if the process can meet Customer CTQs (requirements). Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!Cp and Cpk are used for Process Capability. Generally, you use this when a process is under statistical control. This often happens with a mature process that has been around for a while. Process capability uses the process sigma value determined from either the Moving Range, Range, or Sigma control charts. Pp and PPk are used for Process Performance. Generally, you use this when a process is too new to determine if it is under statistical control. Ex. you are piloting a new process or testing a short pre-production run. Because there is not a lot of historical data, we take large samples from the process to account for variation. Process Performance generally uses sample sigma in its calculation. In theory, Cpk will always be greater than or equal to Ppk. There are anomalies seen when the sample size is small, and the data represents a short amount of time where estimating using R will overstate standard deviation and make Cpk smaller than Ppk. It is not real; there can never be less variation in the long term since the long term is using all of the data, not just two pieces of data from every subgroup. Evaluating process capability with Cp & Cpk mirrors what is done (and why it is done) when following the Pp & Ppk approach. The main difference is that you use Cp & Cpk after a process has reached stability or statistical control. Cpk vs. PpkPpk tells us how a process has performed in the past, and you cannot use it to predict the future because the process is not in a state of control. If a process is under statistical control;The values for Cpk and Ppk will converge to almost the same value because the sigma and the sample standard deviation will be identical (use an F test to determine). In other words, if Cpk == Ppk, the process is likely in statistical control. If a process is NOT in statistical control;Cpk and Ppk values will differ distinctly, perhaps by a very wide margin. What is the Difference Between Cp and Cpk? Cp vs. CpkCp and Cpk measure your consistency compared to your average performance. The ‘k’ stands for ‘centralizing factor.’ The index considers the fact that your data may not be centered. Cpk tells us what a process can do in the future, assuming it remains in a state of statistical control. The Shooting at a Target Analogy Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!In a perfectly centered data set, there will be no difference between Cp and Cpk. Think of throwing darts at a dart board and having the center of the bull’s eye be the 0,0 on a cartesian plane and the edges being out three units from that center point (we will use the edge of the dartboard or 3 and -3 as our USL and LSL). In a perfectly centered sample of darts, your average distance from the center, or Mu, will be 0. A little algebra will show us that your Cpk and Cp numbers are the same. Min((0- -3)/3s , (3-0)/3s) = (3- -3)/6s = 1s . Things get a little harrier when the darts move up, say to be centered at an average of 2 units above center. Now you end up with a Cpk of (3-2)/3s = 1/3s, but your Cp is still the same 1s as before. It is important to note that because Cpk uses the minimum function, it will always be equal to or smaller than the Cp for the same set of data. What is Cpk? The Parking a Car in the Garage AnalogyThink of the walls of your garage – where you have to fit your car – they become the customer specification limits. If you go past those limits, you will crash, and the customer will not be happy! When your process has a lot of variation, the process average is all over the place. Not good for parking a car or any other process. To give your parking process the best chance of success, you should reduce variation and centering. If the car is too wide for the garage, nothing you do to center the process will help. You have to change the dispersion of the process (make the car smaller.) If the car is a lot smaller than the garage, it doesn’t matter if you park it exactly in the middle; it will fit, and you have plenty of room on either side. That’s one of the reasons the Six Sigma philosophy focuses on removing variation in a process. If you have a process that is in control and with little variation, you should be able to park the car easily within the garage and thus meet customer requirements. Cpk tells you the relationship between the car’s size, the garage’s size, and how far away from the middle of the garage you parked the car.” How to Calculate CpkCpk is a measure to show how many standard deviations the specification limits are from the center of the process. On some processes, you can do this visually. Others require an equation. To find Cpk you need to calculate a Z score for the upper specification limit (called Z USL) and a Z score for the lower specification limit (called Z LSL). Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!Since we are trying to measure how many standard deviations fit between the center line and the specification limit, you should not be surprised that the value of those limits, the process mean, and the standard deviation are all components of the Z calculation. Cp is an abbreviation. There are really two parts, the upper and the lower denoted Cpu and Cpl, respectively. Their equations are: Cpl = (Process Mean – LSL)/(3*Standard Deviation)Cpu = (USL – Process Mean)/(3*Standard Deviation) Cpk is merely the smallest value of the Cpl or Cpu denoted: Cpk= Min (Cpl, Cpu) Why are we dividing by 3 to find Cpk?We know that any specification limit has an upper and lower bound. Because you know that 6 sigmas (or six standard deviations account for nearly all eventualities in a process (assuming normal distribution)), you shouldn’t be surprised to see the “/ 3” because we are looking at only one side of the distribution. Calculating Cpk using a Z ValueIf you have a Z value, the equation is very easy; Cpk can be determined by dividing the Z score by three. A z score is the same as a standard score; the number of standard deviations above the mean. Z = x – mean of the population / standard deviation. Notes and Characteristics of Cpk Cpk and Centered ProcessesIf a process is perfectly centered, it has a Cp of 1. That would indicate that the mean was 3 standard deviations away from the upper limit and the lower limit. A perfectly centered process is a process that has a mean exactly in between the 2 specification limits (meaning halfway between the two will have a Cpk of 1. How is this possible? Let’s check the math. If a process is perfectly centered, then we know that the (USL – Process mean) equals the same thing as the (Process Mean – LSL). Let’s call that A. Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!Z USL = USL – Process Mean / Standard Deviation. then becomes Z USL = A/ Standard Deviation Z LSL = Process Mean – LSL / Standard Deviation then becomes Z LSL = A / Standard Deviation. The exact same thing. Notes on Cpk Cpk measures how close a process is performing compared to its specification limits and accounting for the natural variability of the process. Larger is better. The larger Cpk is, the less likely it is that any item will be outside the specification limits. When Cpk is negative, it means that a process will produce output that is outside the customer specification limits. When the process’s mean is outside the customer specification limits, the value of Cpk will be negative. To satisfy most customers, we generally want a Cpk of at least 1.33 [4 sigmas] or higher. Cpk can have an upper and lower value reported. If the upper value is 2 and the lower is 1, we say it has been shifted to the left. This tells us nothing about whether the process is stable or not. We must report the lower of the 2 values. That was poorly centered!

What are Good Values for Cpk? That was poorly centered!

What are Good Values for Cpk?

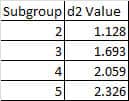

Remember the Car parking in the garage analogy? Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here! Cpk = Negative number: Your process will regularly crash the car into the wall. Cpk =0.5: You have a good chance of hitting the wall on entry. Cpk =1: Your car may be just touching the nearest edge of the entry. Cpk =2: Great! You have great clearance. You could double the width of your car before you hit the side of the garage. Cpk =3: Excellent! You have excellent clearance. You could triple the width of your car before you hit the side of the garage. How to Calculate CpJust as you use Cp & Cpk when a process is stable and Pp & Ppk when a process is new, the way you calculate each is a bit different, too. Let’s revisit Pp Pp = (USL – LSL) / 6* s In Pp, s is the standard deviation or the ‘fatness’ or dispersion of the bell curve. In Cp, we replace s with an estimate of σ we call σr. To do that, we leverage the Moving Range concept from a Moving R Bar chart or an XMR Chart. So, σr = [ R Bar / d2] R Bar comes from the Moving range. D2 reflects values derived from integrating the area under the normal curve. We often use a table that gives a d2 value based on how many subgroups were in the sample.  d2 subgroup values d2 subgroup values

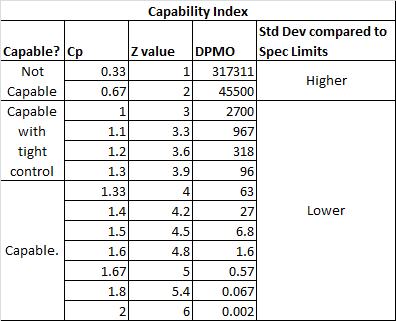

Cp does not account for centering. First, Cp = (USL – LSL) / ( 6* σr ) Second, Cp = (USL – LSL) / ( 6* R Bar / d2 ) Cp for Process Mean close to USLIf your Process Mean (central tendency) is closer to the USL, use: [ USL – x(bar) ] / [3 * R Bar / d2], where x(bar) is the Process Mean. Cp for Process Mean close to LSLIf your Process Mean (central tendency) is closer to the LSL, use: [x(bar) – LSL ] / [3 * R Bar / d2], where x(bar) is the Process Mean. Capability IndexHow do Cp, Z values, DPMO, Specification Limits, Standard Deviation, and Capability all relate? Also, see Z values and process capability.  Capability Index

Notes on Cp Values

Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!

If the ratio is greater than one, then the Engineering Tolerance is greater than the Process Spread, so the process has the “potential” to be capable (depending on process centering).

If the Process Spread is greater than the Engineering Tolerance, then the process variation will not “fit” within the tolerance, and the process will not be capable (even if the process is centered appropriately).

Capability Ratio Cr Capability Index

Notes on Cp Values

Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!

If the ratio is greater than one, then the Engineering Tolerance is greater than the Process Spread, so the process has the “potential” to be capable (depending on process centering).

If the Process Spread is greater than the Engineering Tolerance, then the process variation will not “fit” within the tolerance, and the process will not be capable (even if the process is centered appropriately).

Capability Ratio Cr

The capability ratio is the inverse of Cp Cr = 1/ Cp = ( 6* σr ) / (USL – LSL) If Cr < 0.75, the process is capable. If Cr = 0.75 – 1.00, the process is capable of tight control. When the Cr >1, the process is not capable. Notes on Relating Cp And Cpk If Cp == Cpk, then the process is perfectly centered. If perfectly centered, Cp == Cpk. Because Cpk accounts for centering (where Cp does not), Cpk can never be larger than Cp. Both assume a stable process. Process Capability Videos Cpk VideosGreat, clear, concise video on this subject. “If you were producing a Cpk equal to 1, then you could expect to produce at least 99.73% good parts.” Lecture on Process Capability and SPC ASQ Six Sigma Black Belt Certification Process Capability Questions:Question: Data being used in the initial set-up of a process is assumed to have a normal distribution. If the nominal (target) is set at the center of the distribution, and the specification limits are set at ±3s from the center, then the Cpk is equal to: Don’t like Ads? Neither do I. If you’re a member, just log in to avoid ads. If you’re not a member, what are you waiting for? Sign up here!(A) –0.25(B) 1.00(C) 1.33(D) 1.67 Answer: Unlock Additional Members-only Content! To unlock additional content, please upgrade now to a full membership. Upgrade to a Full Membership If you are a member, you can log in here. Thank You for being a Member! Here’s some of the bonus content that is only available to you as a paying member.C: The range of the process is represented by 6 sigmas – or standard deviations in the Cp Index equation. Remember, 6 standard deviations account for nearly all eventualities (assuming normal distribution) of the process. 6 sigmas are a good approximation of the range of outcomes. The USL – LSL (the upper and lower limits) could be representative of the tolerance interval. I’m not familiar with anything called the tolerance interval, but the upper and lower limits are set by what is considered acceptable by the client. And those fit. A confidence interval is a statistical measure used in hypothesis testing and is not pertinent to this question. Variance is a specific term in Six Sigma. You can calculate variance by squaring the standard deviation – a term that does not appear in the Cp equation so we can eliminate this answer. Cp, Cpk, Pp, Ppk Practice Questions and Z Charts

Practice makes perfect! Free Cp, Cpk, Pp, Ppk practice questions. Success! Now check your email to confirm your subscription. Authors Ted Hessing

Ted Hessing I originally created SixSigmaStudyGuide.com to help me prepare for my own Black belt exams. Overtime I've grown the site to help tens of thousands of Six Sigma belt candidates prepare for their Green Belt & Black Belt exams. Go here to learn how to pass your Six Sigma exam the 1st time through! View all postsView all posts |

【本文地址】